Selecting the Right Dryer to Remove Moisture from Compressed Air

air compressor manufacturers in india

Selecting the Right Dryer to Remove Moisture from Compressed Air

Compressed air is the lifeblood of countless industries in India, powering everything from factory machinery to medical equipment. But here's the catch: compressed air naturally contains moisture, and in India's humid climate, this moisture can wreak havoc on your entire system.

Think about it - leading air compressor manufacturers in India

constantly emphasize the importance of proper air treatment. Did you know that even a small amount of moisture can lead to rust, corrosion, and malfunctioning equipment? In fact, a study by the Compressed Air and Gas Institute (CAGI) found that uncontrolled moisture can increase maintenance costs by a staggering 30%!

That's where compressed air dryers come in. These clever devices remove moisture from the compressed air stream, protecting your equipment and ensuring smooth operation. But with so many dryer options available, choosing the right one can be a challenge. This guide will help you navigate the world of compressed air dryers and select the perfect solution for your needs in India.

1. Why Remove Moisture from Compressed Air in India?

India's hot and humid climate is a breeding ground for moisture problems in compressed air systems. Here's why removing moisture is crucial:

- Impact of Humidity: Moisture in compressed air can lead to:

- Rust and Corrosion: The combination of moisture and compressed air creates a perfect storm for rust and corrosion. This can damage pipelines, valves, and other critical components, leading to expensive repairs and downtime.

- Malfunction: Moisture can interfere with the operation of pneumatic tools and machinery. Imagine a critical production line coming to a halt because a moisture droplet caused a malfunction in a key component!

- Product Contamination: In moisture-sensitive applications like food processing and pharmaceuticals, even a trace amount of moisture can contaminate the final product, leading to costly product recalls and safety concerns.

- Examples of Moisture-Sensitive Applications in India: Several industries in India rely on clean, dry compressed air:

- Pharmaceuticals: Moisture can affect the stability and effectiveness of medications.

- Food Processing: Moisture can promote bacterial growth and spoilage in food products.

- Electronics Manufacturing: Moisture can damage sensitive electronic components.

2. Types of Compressed Air Dryers

There are two main types of compressed air dryers used in India:

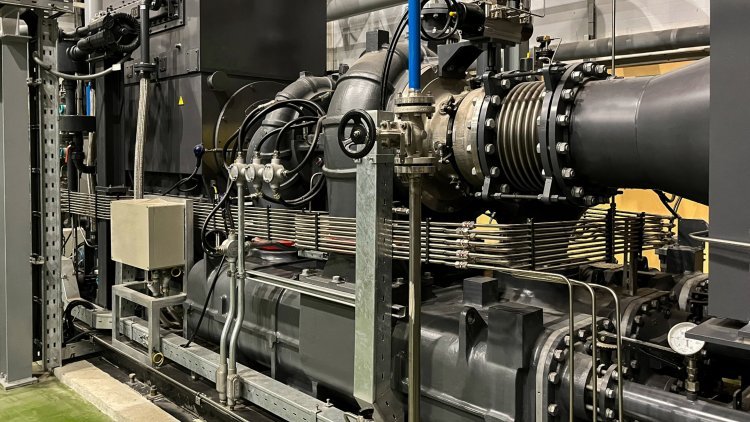

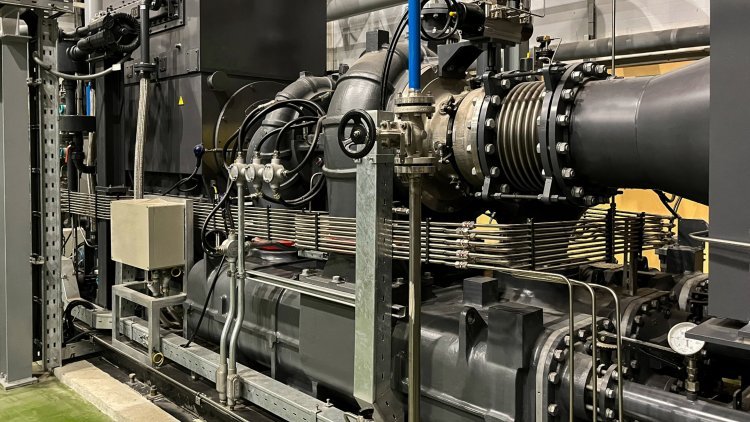

- Refrigerated Air Dryers:

- Working Principle: These dryers work similarly to your home refrigerator. Compressed air is passed through a heat exchanger, where it's cooled down to a certain temperature (dew point). This cooling causes moisture to condense out of the air, forming water droplets which are then drained automatically.

- Advantages:

- Cost-effective: Refrigerated dryers are generally less expensive to purchase and maintain compared to desiccant dryers.

- Simple Operation: They require minimal user intervention and are relatively easy to maintain.

- Limitations:

- Dew Point Limitations: Refrigerated dryers can only achieve a certain dew point, typically around +3°C (37°F). This may not be suitable for all applications.

- Not Ideal for All Applications: They are not ideal for very critical applications requiring extremely dry air.

- Desiccant Air Dryers:

- Working Principle: These dryers utilize a desiccant material, like silica gel or activated alumina, to absorb moisture from the compressed air. The desiccant acts like a sponge, attracting and holding onto moisture molecules. Once saturated, the desiccant is regenerated through a process involving heat or purging with dry air to release the trapped moisture and restore its capacity.

- Advantages:

- Very Dry Air Achievable: Desiccant dryers can achieve extremely low dew points, down to -70°C (-94°F), making them ideal for applications requiring very dry air.

- Ideal for Critical Applications: They are perfect for moisture-sensitive processes where even a trace amount of moisture can be detrimental.

- Limitations:

- Higher Initial Cost: Desiccant dryers are typically more expensive to purchase upfront compared to refrigerated dryers.

- Require Regeneration: The regeneration process consumes additional energy and requires maintenance for smooth operation.

Choosing Between Refrigerated and Desiccant Dryers: The right choice depends on your specific needs. Refrigerated dryers are a good option for most general applications where the dew point requirement is not extremely low. Desiccant dryers are ideal for critical processes requiring very dry air, such as those mentioned earlier.

What's Your Reaction?

![Wireless Connectivity Software Market Size, Share | Statistics [2032]](https://handyclassified.com/uploads/images/202404/image_100x75_661f3be896033.jpg)